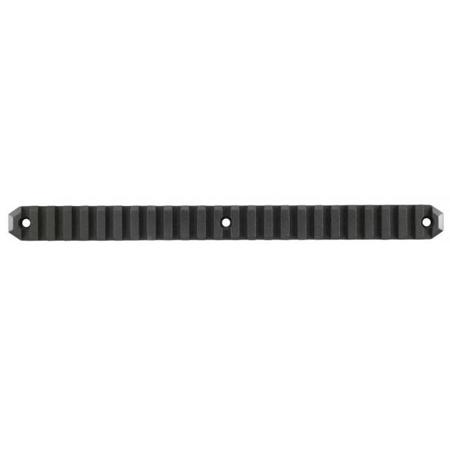

Designed to mount heavy sights of various kinds, a great variety of accessories and attachments are now available and the rails are no longer confined to the rear upper surface ( receiver) of long arms but are either fitted to or machine milled into the upper, side or lower surfaces of all manner of weapons from crossbows to pistols and long arms up to and including anti-materiel rifles. Whereas the earlier Weaver rail is modified from a low, wide dovetail rail, the Picatinny rail has a more pronounced angular section. The spacing of slot centres is 0.394 in (10.01 mm) and the slot depth is 0.118 in (3.00 mm). The Picatinny locking slot width is 0.206 in (5.23 mm). It is similar in concept to the earlier commercial Weaver rail mount used to mount telescopic sights, but is taller and has wider slots at regular intervals along the entire length. The rail consists of a strip undercut to form a "flattened T" with a hexagonal top cross-section, with cross slots interspersed with flats that allow accessories to be slid into place from the end of the rail and then locked in place. Ī metric-upgraded version of the Picatinny rail, the STANAG 4694 NATO Accessory Rail, was designed in conjunction with weapon manufacturers like Aimpoint, Beretta, Colt, FN Herstal and Heckler & Koch, and was approved by the NATO Army Armaments Group (NAAG), Land Capability Group 1 Dismounted Soldier (LCG1-DS) on May 8, 2009.Ĭurrently, many firearm manufacturers include a Picatinny rail system out of factory, such as the Ruger Mini-14 Ranch Rifle. After it was determined that the new rail should be a standard, not a specification, it was adopted and fielded in 1995 with the designation MIL-STD-1913, dated February 3, 1995. The team then sent the finished prototype over to Rock Island Arsenal for review and trial, and then to the technical data section to determine if it should be a standard or a specification. The factory recognized the similarity of the purposed rail interface to the existing rail design on 105 mm howitzers, so they chose to scale down the howitzer rail design and co-opted the production and inspection procedures. Houtsma then took the specifications over to the production facility and requested they design a dimensioning style so the rail could be easily produced and inspected. The Picatinny team was headed by mechanical designer Gary Houtsma (who was awarded the Order of Saint Maurice Award in 2014 for this contribution ), who took the measurements from 20 or so different Weaver rail products from weapons bunkers at Picatinny (and even local sporting goods stores) and came up with an average set of numbers set on a 45-degree angled surface. Army was dissatisfied with the contemporary products on the market.

The rail itself is named after the Picatinny Arsenal in New Jersey, which was named "after the Lenape-named peak overlooking the old forge, loosely translated to mean 'rugged cliff by water' or 'water by the hills'." The Picatinny Arsenal was tasked in 1992 to develop a standardized mounting system after the U.S. These were the M16A2 and the M4 modified with new upper receivers where rails replaced hand guards. Specifications for the M16A2E4 rifle and the M4E1 carbine received type classification generic in December 1994. History Īttempts to standardize the Weaver rail designs date back to the early 1980s from work by the A.R.M.S. Their usefulness has led to them being used in paintball, gel blasters and airsoft. Because of their many uses, Picatinny rails and accessories have replaced iron sights in the design of many firearms, and they are also on the undersides of semi-automatic pistol frames and grips.

0 kommentar(er)

0 kommentar(er)